- Success stories

- AI-Powered Workplace Monitoring System for Industrial Equipment Safety

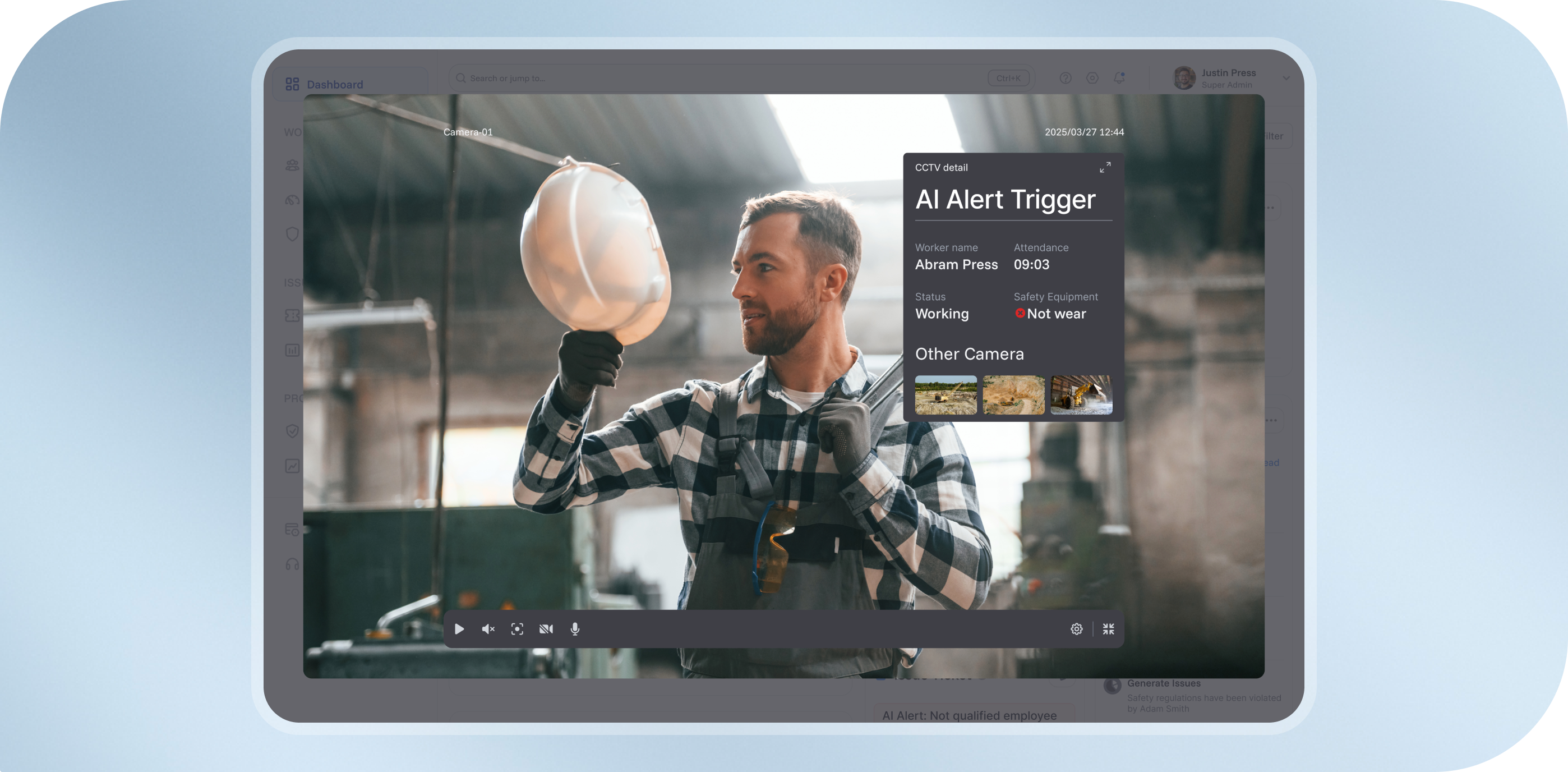

AI-Powered Workplace Monitoring System for Industrial Equipment Safety

Computer vision software for compliance, safety, and efficiency on the shop floor

Project background

Overview

The client operates heavy machinery and wanted to ensure that only authorized personnel interact with the machines, that all employees follow safety guidelines, and that any violation triggers immediate alerts.

The client had limited technical background in computer vision and AI but understood the potential benefits. Initially, they were unsure how to achieve real-time monitoring, and whether existing hardware could support it. Our role was to guide them through the technology selection, implement an AI-based solution, and ensure seamless integration with their machinery and operations.

Project Goals

- Detect multiple people near a machine and notify a supervisor in real time.

- Detect absence of protective clothing and disable machine operation automatically.

- Track and analyze hand movements to ensure safety and operational efficiency.

- Build a live monitoring dashboard for supervisors.

- Provide statistical dashboards with historical data and visual insights.

- Webapp

- 5team members

- 800+hours spent

- AI & Analyticsdomain

Challenges

- Achieving high detection accuracy in variable lighting and camera angles.

- Integrating real-time video analytics with existing industrial machinery.

- Fast response time to enable immediate machine shutdown.

- Designing an interface usable by non-technical supervisors.

Our approach

Solution

We began by collecting annotated video data directly from the client’s facility. Our ML engineer fine-tuned YOLO-based models to detect human presence, safety clothing, and specific hand gestures. Meanwhile, the development team built an interface that connects AI predictions to machine control logic with automated shutdowns or alerts. We created two dashboards: one for real-time monitoring and another for viewing statistics over time. These dashboards were built with web technologies and connected to a backend service managing device inputs and alerts. Throughout the process, we collaborated closely with the client’s technical and operations teams to ensure all rules and workflows reflected real industrial constraints and operator behavior.

Team

The team consisted of a computer vision specialist responsible for training and optimizing YOLO models, a backend developer working on machine integration and real-time processing, one frontend developer for the dashboard interfaces, and a QA specialist handling regression and safety-critical test scenarios. The project manager ensured smooth communication with the client and quick iteration on feature requests.

Results

The system successfully detected violations in real-time and blocked machine operation in cases of missing protective gear. It also identified unauthorized personnel near the machines and notified supervisors instantly. The dashboard helped managers analyze incident trends and improve shift planning. The client reported a 60% drop in safety incidents and saw measurable improvement in compliance rates during the first 3 months of rollout.

The solution was adopted across three additional facilities within six months of launch. The client presented the system at an industrial safety conference, receiving interest from other manufacturers. It became part of their company-wide safety initiative and is now a key component of their ISO compliance documentation.

Tools and tech stack

More Projects

- agritech

- analytics

- webapp

- saas

- python

- webapp